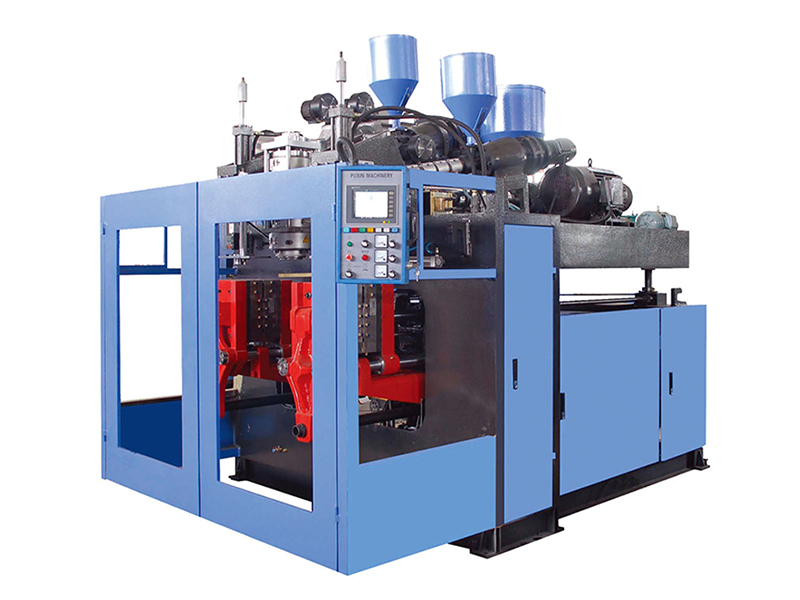

Basic Equipment

| Clamping system | Diagonal two tie bar center clamping bi-directional synchronous high prexision linear guiding clamping device |

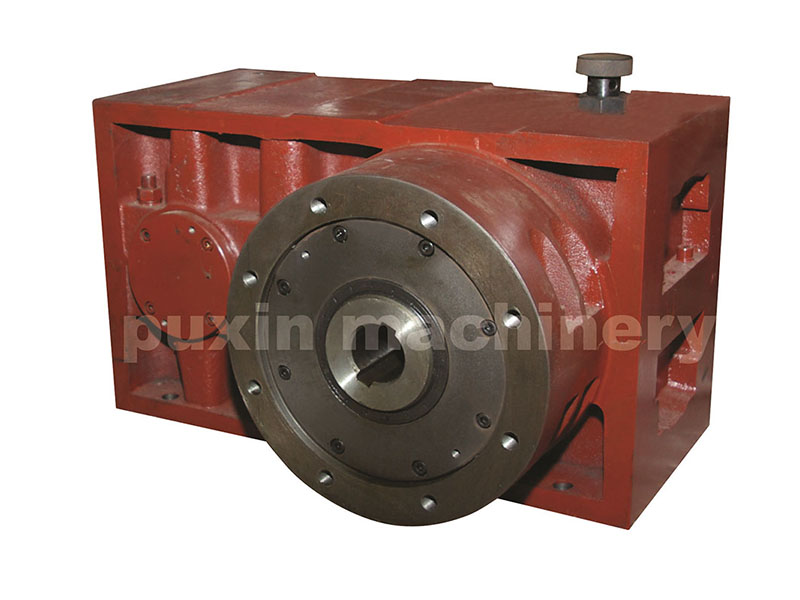

| Extrusion System | Hard gear surface decelerator+imported DC drive |

| Die system | Accumulator head |

| Hydraulic system | Japan hydraulic valve seal and proportional control |

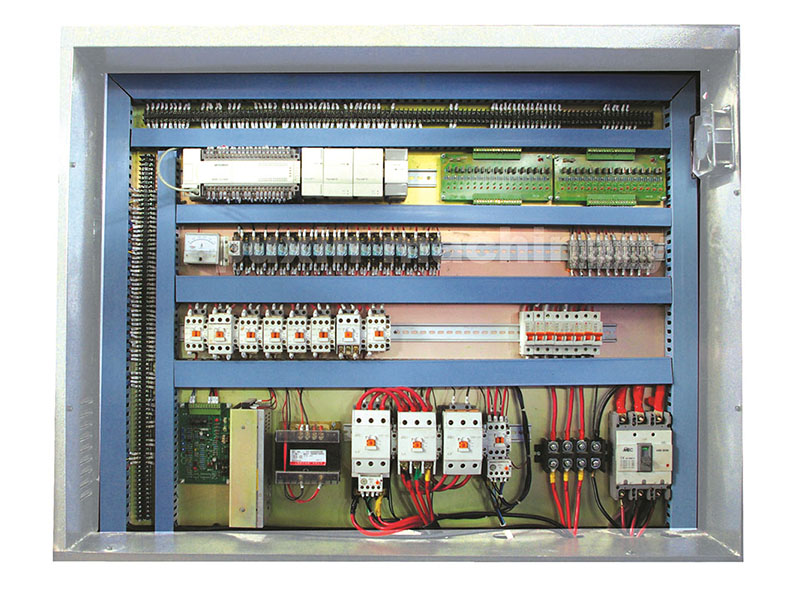

| Control system | Whole set of European closed-loop bi-proportional control system |

Parameters

| Specifications | ||

| Material | PE,PP, … | |

| Max container capacity | L | 230 |

| Output(dry cycle) | Pc/hr | 180 |

| Machine Dimension(LxWxH) | M | 9.5x4.1x6.5 |

| Total weight | T | 36 |

| Clamping Unit | ||

| Clamping force | KN | 800 |

| Platen opening stroke | mm | 800-1700 |

| Platen size | mm | 1200x1300 |

| Max mould size(WxH) | mm | 950x1600 |

| Mould thickness | mm | 900-960 |

| Power | ||

| Max drive | KW | 138 |

| Total power | KW | 180 |

| Fan power for screw | KW | 0.25x6 |

| Extruding motor | KW | 112 |

| Hydraulic pump motor | KW | 22+5.5 |

| Air pressure | MPA | 1 |

| Air consumption | M3/min | 3 |

| Average energy consumption | KW | 140 |

| Extruder unit | ||

| Screw diameter | mm | 120 |

| Screw L/D ratio | L/D | 30 |

| Melting capacity | Kg/hr | 320 |

| Number of heating zone | zone | 6 |

| Extruder heating power | KW | 39 |

| Die | ||

| Number of heating zone | zone | 6 |

| Power of die heating | KW | 38 |

| Max die-pin diameter | mm | 500 |

| Accumulator capacity | L | 22 |

dd

PRODUCT CATEGORY

Single Station Automatic

- PXB70D Series

- PXB70 Series

- PXB90D Series

- PXB90 Series

- PXB110 Series

- PXB200L Series

- 5ml-2L Single Station PXB50

- 2L-5L Single Station PXB65

- 5L-12L Single Station PXB70

- 20L-30L Single Station PXB80

- 30L-60L Single Station PXB90

- 60L-90L Single Station PXB100

- 60L-120 L Single Station PXB...

- 120 L-160L Single Station PX...

- 460L-500L Single Station PXB...

- 200L-220L Single Station PXB...

Double Station Automatic

Parts